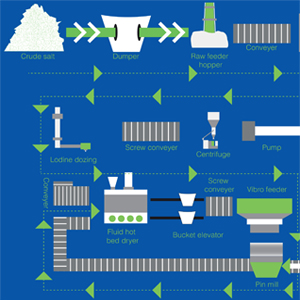

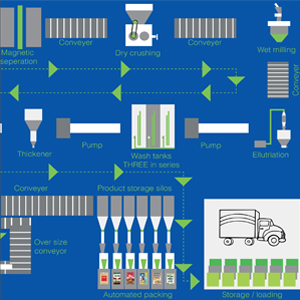

Process Sequence

Production Line Configuration

Salt feeding, Washing, Milling

The Crude raw salt from various salt fields is brought by dumpers and unloaded directly in raw salt hopper and it is then transferred to A belt conveyor, which are fitted with magnets to remove any iron particles and inclusions from the material. Crude salt is pre washed in special washing system. This is then fed to the feed in hopper of the wet mill for grinding. Wet mill is used to grind the salt with the help of saturated brine solution. This mixture is passed to slurry tank that is fitted with low speed agitators.

Centrifuge / Iodisation Section

Vibrant Global group is spearheaded by Mr. Vinod Garg, who carries with him a rich industrial experience spanning nearly 33 years wherein he has held various positions in Ispat Industries Limited. He was on the Board of Ispat Industries as Executive Director-Commercial for more than a decade. He was responsible for entire supply chain functions at Ispat Industries Ltd including purchase of all raw materials and consumables and sales and marketing of all products of the company. This portfolio of business handled by Mr Garg in this tenure was to the tune of more than 2 Billion USD per annum.He is well known in the steel industry for his sharp commercial acumen, analysis and reading of the steel market and initiating reforming measures for the steel industry in particular that has led to several new policies and measures being introduced at the Government level for steel industry. He has been a member of various policy guiding bodies and associations such as CII, ASSOCHAM,FICCI, CORSMA, ISA.

Drying & Finished Product Handling Section

The salt crystals from the centrifuge are dried in a Fluid-Bed Dryer. The crystals forms a layer on the perforated sheet present in the drying chamber of the fluid bed dryer and is dried by means of hot air from a thermio air heating/Indirect air heating system.We have a state of the art boiler from Heatex and huge ID and FD fan combination that ensures proper negative pressure in the dryer and ensures drying in fully dry condition. cyclone separator and are collected separately. Dry passed to the rotary vibro feeders through a bucket elevator. The oversized salt is separated in these vibro feeders and the over sized salt crystals is passed to the pin mill for further grinding.Thus, the Automatic Vibro feeders separate the correct particulate size required for packing of bucket elevators to large storage silos.

Automatic Packing

Vibrant Global group is spearheaded by Mr. Vinod Garg, who carries with him a rich industrial experience spanning nearly 33 years wherein he has held various positions in Ispat Industries Limited. He was on the Board of Ispat Industries as Executive Director-Commercial for more than a decade. He was responsible for entire supply chain functions at Ispat Industries Ltd including purchase of all raw materials and consumables and sales and marketing of all products of the company. This portfolio of business handled by Mr Garg in this tenure was to the tune of more than 2 Billion USD per annum.He is well known in the steel industry for his sharp commercial acumen, analysis and reading of the steel market and initiating reforming measures for the steel industry in particular that has led to several new policies and measures being introduced at the Government level for steel industry. He has been a member of various policy guiding bodies and associations such as CII, ASSOCHAM,FICCI, CORSMA, ISA.

Fully Automated Electrical Control Systems

Vibrant Global group is spearheaded by Mr. Vinod Garg, who carries with him a rich industrial experience spanning nearly 33 years wherein he has held various positions in Ispat Industries Limited. He was on the Board of Ispat Industries as Executive Director-Commercial for more than a decade. He was responsible for entire supply chain functions at Ispat Industries Ltd including purchase of all raw materials and consumables and sales and marketing of all products of the company. This portfolio of business handled by Mr Garg in this tenure was to the tune of more than 2 Billion USD per annum.He is well known in the steel industry for his sharp commercial acumen, analysis and reading of the steel market and initiating reforming measures for the steel industry in particular that has led to several new policies and measures being introduced at the Government level for steel industry. He has been a member of various policy guiding bodies and associations such as CII, ASSOCHAM,FICCI, CORSMA, ISA.

The Chart Showing the Process